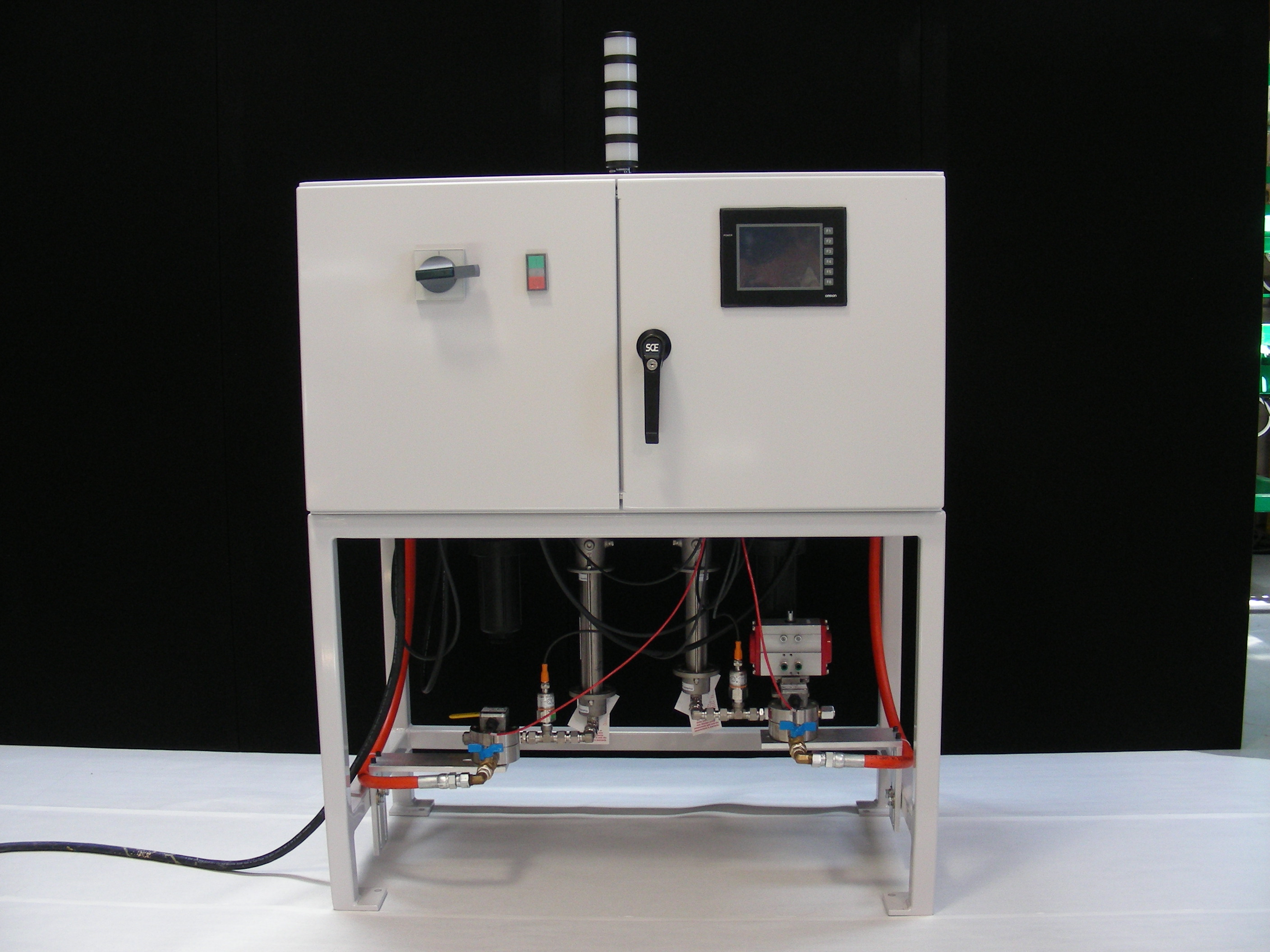

Meter Mixer M2

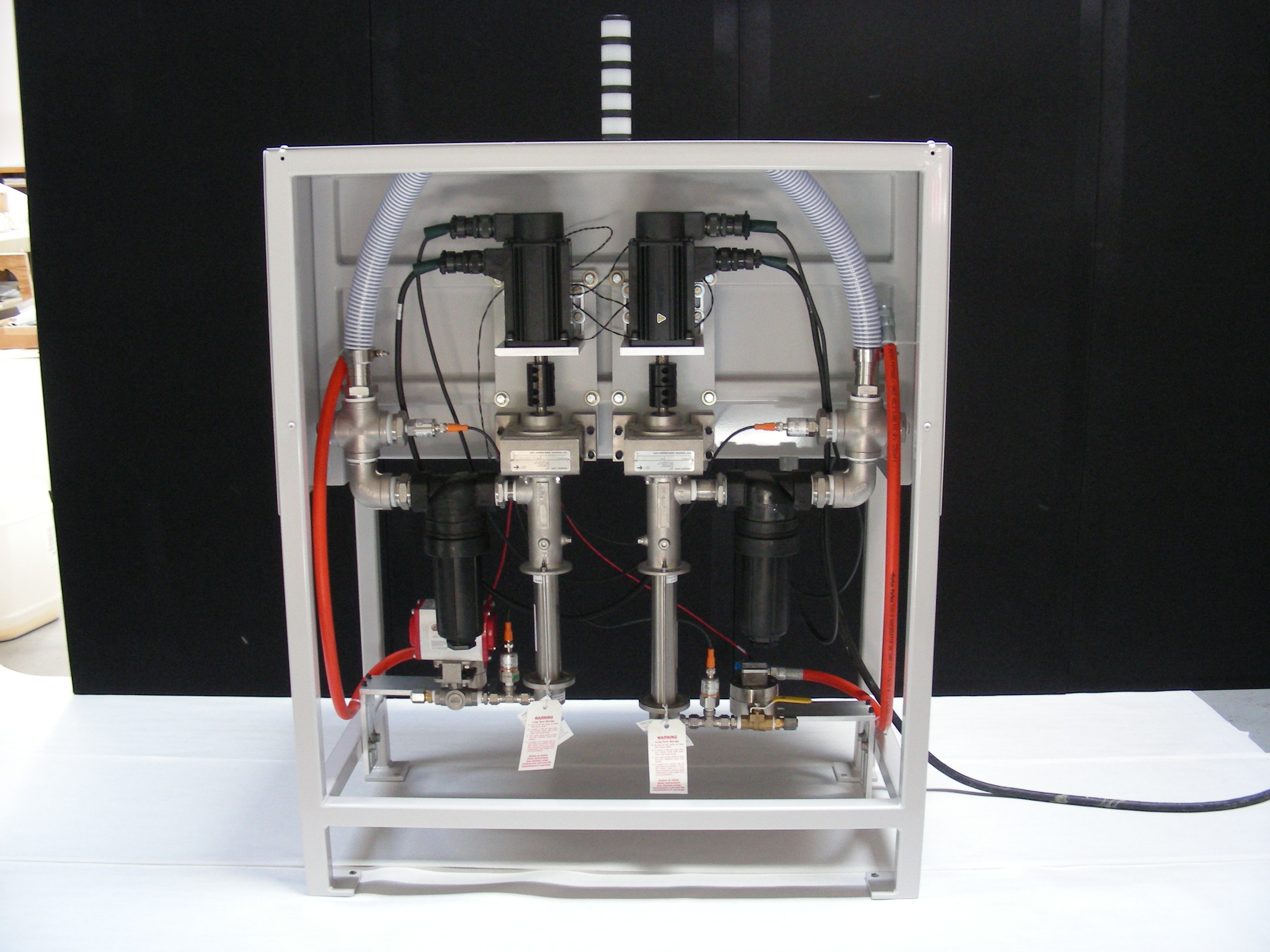

The Apquip meter mixing system utilizes progressive cavity pumps along with gear meters to assure an exact ratio mix of plural component adhesives. Servo motors and drives control output of each component thru the progressive cavity pumps. Inline monitoring of each component after discharge from the pumps includes pressure sensing, temperature sensing and volume sensing. The added benefit of checking flow rates of each component after the pumps is that once the proper ratio has been achieved, there is minimal need for further ratio checks and absolute certainty of proper ratio within set parameters. If ratio, temperature or pressure is out of set tolerance, alarm will immediately signal operator or shut down.

- Touch screen allows for change of ration, delivery rate, parameters and settings in seconds.

- Constantly monitor ration, flow rates, pressure and temperature.

- Material for pump rotor, pump stator and flow meters specified individually for customer resin and catalyst.

- 316 stainless compression fittings for ease of assembly and longevity.

- Fully enclosed electronics and open rack mounting of wetted parts for accessibility.

- Automatic flushing of one or both components thru three way ball valves for quick clean-up.

- Can be used for lamination lines, finger jointers, roll coaters, I-beams or applications where two component mixing is required.

- Stack LED lighting for quick assessment of operational status.